11-08-2004

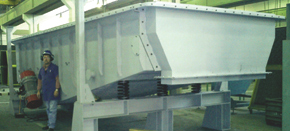

Full scale pilot plant for the continuous drying of charcoal with VIPROC fluidized bed vibratory conveyors.

In order to obtain greater efficiency during the charcoal grinding process for metalurgical purposes, Mavi is participating in a joint effort to set up an experimental full scale plant to reduce to appropriate levels of humidity something around 50 m3/h of reforestation derived charcoal.

This process is required during the rainy season in order to achieve a constant flow of charcoal powder for the operation of blast furnaces.

The drying media is burnt blast furnace gas which will be conducted to the vibratory equipment, forming the fluidized bed required for this operation.

The final stages of assembly are under way and most probably until the end of 2004 first test results will be obtained.