03-03-2009

2009 not yet the expected catastrophe for Latin America and its bulk process equipment manufacturers

Despite the world financial crisis and less orders from the so called first world countries, Mavi has suffered less than expected.

Our position among machinery manufacturers in Latin America has consolidated itself to a stable standard, with interesting sales to Peru, Colombia, Venezuela, Southern USA, Mexico and Chile during 2008 and expecting a similar but surely little smaller total sales for 2009.

But not as catastrophic as we initially expected. As the Brazilian real lost its value towards the US dollar, freight prices decreased significantly and third party labor costs plunged accordingly, Mavi has kept quality and delivery schedules with much lower prices.

With less exposure to the banking system and financing needs, in fact none at all, Mavi is stil a reliable source for modern vibratory equipment since 1961.

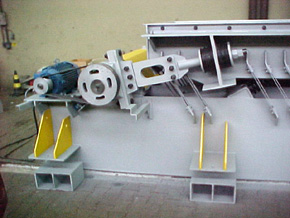

All types of vibratory drives, light and heavy equipment from screeners to feeders, from vibrating tables to long conveyors produced in Brazil, exported throughout the world. For more on us, have a look at the pictures.