21-10-2010

Looking better

The prospects are looking a little better in Latin America. For the end of 2010, with Mavi preparing to rush into its 50th year of existence, some interesting larger orders were placed and are being delivered.

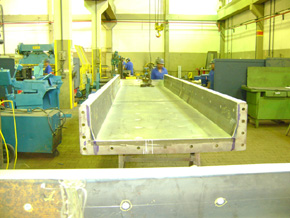

For example two large castings coolers for an automotive foundry in the state of Minas Gerais, complete with electronic controls, special ventilating hood, super anti-abrasive linings and temperature control by infrared measuring coupled to a water spraying device, to cool castings a little more.

23.000 mm long, the smaler unit and 25.000 mm the larger one.

Mavi is the sole manufacturer of castings coolers in Latin America, with local technical assistance and the folks who do it speaking the languages.

And despite fierce competition from the Far East, a real problem nowadays with very cheap equipment being sold down here, Mavi managed to close an important contract for all of the screening and vibratory feeding and conveying for a larger steel shot producing operation in southern Brazil.

The traditional round screeners from Mavi were the choice due to their known sturdiness, the Vimot vertical drives either with special roller bearings and of course the technical assistance and replacement in the future, still a little problematic for vibratory equipment suppliers as far as Bulgaria or Taiwan exercising their sales efforts here .

The sugar industry has not forgotten to revamp their older factories and three large Revitran conveyors are to be delivered until December, all stainless steel, the new trend. And a large steel producing site in Minas Gerais has ordered 35 large electromagnetic feeders for their new facility, a very welcome order.

Anyway it looks better after 2 years in deep recession for our sector and terrible if not predatory competition from far away.