Applications

VICAL® vibrating conveyors are mainly employed for unloading bulk materials from silos and bins, as well as for conveying or dosing.

The conveyor channel, rectangular, trapezoidal, or semicircular in shape, undergoes linear vibrations under a small angle of inclination. These vibrations activate the product to be transported by micro-bounces, producing a smooth movement, with no damage to the conveyor trough.

The trough oscillation (double amplitude) is on the order of 4 to 6 mm and the corresponding conveying velocity varies from 15 to 35 cm/s.

The vibratory feeder channel can be adjusted to achieve different conveying capacities by adjusting the inertial weights attached to the shaft ends of the vibrators.

The adjustment can be checked in the VIMOT® Service Manual or in the corresponding brochure.

All bulk materials, from the bulkiest to those with powder consistency and granulation, are transportable. Materials that tend to drip (cement) can present problems and therefore need further examination by the manufacturer.

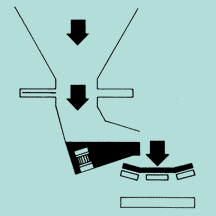

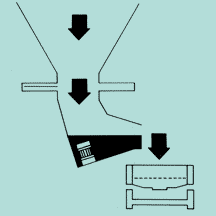

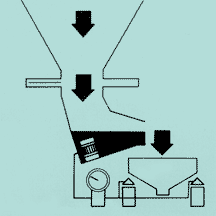

Below are three application examples: feeding a belt, a sieve, and a scale.