Working principle

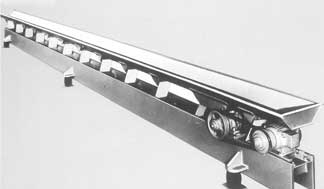

Detalhe mostrando molas helicoidais de aço utilizadas nos transportadores Revitran

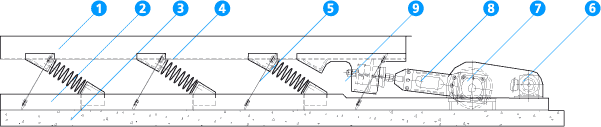

Revitran® type vibratory conveyors, models SKL and SKF, consist of a mass-spring system, including the conveyor trough itself (1), the counterbalance (2) consisting of the foundations (3) and lower structure or a mass of defined size, and the steel coil springs.

Depending on the size of the mass and the number of springs, this set has a defined natural frequency. Activating the system with cyclic pulses starts the vibratory movement. The ratio of amplitudes is inversely proportional to the ratio of masses between the chute and the counterbalance, that is, the larger the counterbalance, the smaller its amplitude.

When mounted directly on the ground, the counter-balance becomes infinitely large and amplitude tends to zero. Then practically only the vibration of the chute through which the bulk material is conducted occurs. This vibration drives the material to micro-bounces creating a uniform flow. The launch is guided by the lateral flat springs (5).

If the system is activated with pulses coinciding with the natural frequency of the spring-mass assembly, resonance will occur, no matter how small the applied forces are, already managing to induce the assembly to vibrations. The great advantage of this system is therefore the minimal energy consumption. This small force required is transmitted to the assembly by the motor (6), the reduction gear (7), and the connecting rod-crank system (8) connected to the conveyor chute by the coupling springs (9).

The vibratory channel's trajectory corresponds to simple harmonic (sine) motion with the familiar acceleration and deceleration phases. Vibratory transport occurs because the material takes off from the accelerated surface in the outward motion, initiating the oblique throw and the parabolic trajectory, while the surface is then decelerated.

Since the parabolic trajectory is short (micro-bounce) and the frequency relatively high, the sequence of impacts is such that the flow of material becomes uniform.