Construction

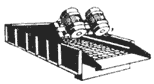

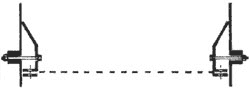

Basic unit, consisting of a screening box, bottom drive by 2 VIMOT vibrators, discharge nozzles and a set of support springs.

Basic unit. Same features as described alongside, but with the vibrating drive at the top.

Protective cover that can be attached to the top of the sieve box to prevent the spread of dust.

Spare screen frame in case you need to change screens.

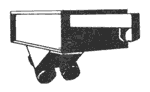

Feed hopper, which can be attached to the standard support.

Standard support for VELOPEN screens, made of ABNT 1020 steel profiles.

Fastening and tensioning methods for screens and perforated plates

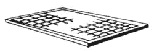

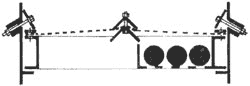

A - Drawer frame made of metal profiles for VELOPEN screens of 1 to 3 planes exclusively for fine metal screens with mesh openings of 0.1 to 6.0 mm. Screens bolted to the frame and tensioned by means of a central corner in a lateral direction. The frame is fixed to the side of the screening box using flat bars. Below is a “no-blind” device with rubber balls which, activated by vibration, strike against the screen above, cleaning it and thus preventing the meshes from being clogged.

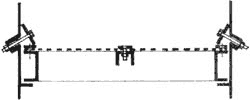

B - Metal profile drawer frame for VELOPEN screens from 1 to 3 planes. Can be used for mesh and coarse wire as well as perforated plates. There is no tensioning device, the screens and plates are bolted together. The frame is fixed to the sieve box from the side using flat bars.

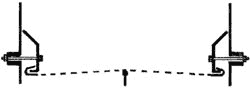

C - Clamping and lateral tensioning device for mesh and fine wire perforated screens and sheets. The meshes or sheets are screwed onto the fixing bars. The necessary tensioning is carried out with these same bars using screws. This type of fixing is recommended for 1-plane VELOPEN screens.

D - Lateral clamping and tensioning device whose principle is similar to that described under item “C”, except that it can only be used with screens fitted with hooks on their sides. It is recommended for VELOPEN screens with 1 to 3 planes.