Advantages and options

- Processed parts are automatically separated from the abrasive bodies.

- It can work continuously or in batches.

- In the batch process, the system can be automated with the use of a timer to regulate the processing time and a pneumatic cylinder to actuate the unloading ramp.

- It can be programmed for sequential operations such as washing, drying, rust cleaning, polishing, and separating parts from chips.

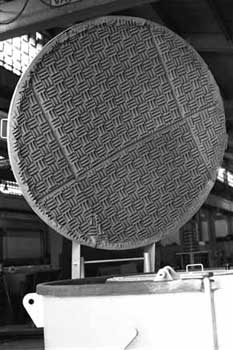

- The separation screen can be designed to separate the undersized, broken, and thin chips generated during the process.

- Automatic separation between parts and chips reduces setup time between workloads by up to 90%.

- Compact construction, with the composite circulation tank attached to the machine base.

- No special base is required to fix it to the floor.

- MAVITRON is self-cleaning, and the chip discharge is done through the discharge ramp by placing a smooth plate over the screen.

- The vibratory amplitude is variable with the adjustment of the counterweights to allow adaptation to the work needs, influencing the horizontal and vertical trajectory of the work load.

- Besides working with a low noise level, it can be supplied with a lid with acoustic coating.

- MAVITRON can offer 2 compound utilization systems: constant flow or recirculation.

- All operations are controlled from the control panel.

- The tubular shape of the MAVITRON track allows uniform finishing throughout the batch of processed material.

- The unloading ramp can have manual or automatic actuation.

- In case of automatic operation, vibrating chutes for feeding and unloading can be supplied.

- An optional vibratory frequency variation system allows greater flexibility in controlling the degree of finishing.

- The MAVITRON operating system allows for savings in abrasive media, because it reduces the need for handling and losses.

- MAVITRON machines process cast, stamped, forged, machined, and injected parts, of ferrous and non-ferrous materials, in deburring, polishing, cleaning, and grinding operations.