Applications

VICAL-T vibratory feeder troughs are mainly used for conveying bulk materials and can convey distances of up to 6.5 m, or more when combined in groups to form conveying lines. They can be fed at one or more points along the route they cover, as well as unloaded. In addition, the bulk materials conveyed can be subjected to different processes such as cooling or heating, drying, wetting, screening, etc. We will go into more detail later, under the heading Planning.

It is important to remember that the chutes, rectangular, trapezoidal, or semicircular, suffer linear vibrations under a certain angle of inclination. These vibrations activate the product to be transported to micro jumps, producing a smooth flow, not occurring excessive abrasion of the chute.

The VICAL-T vibratory conveyor chute can be adjusted to achieve different conveying capacities by adjusting the inertial weights attached to the shaft ends of the VIMOT vibrators (see Drive).

All bulk materials, from the bulkiest to those with the consistency and graininess of powder, are transportable. Materials with a tendency to run off, such as cement, for example, can present problems and therefore need further examination by the manufacturer.

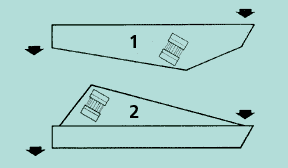

The diagrams below show two executions of VICAL-T vibratory conveyor chutes. In the first schematic (1) you can see the positioning of the vibratory drive, located at the bottom of the chute. In the second diagram (2) the location is at the top.