Engineering

Nowadays customers demand from equipment manufacturers a little more than the bulding and simple delivery of equipment. Sometimes complete solutions are a must and necessary for the optimized operation of an industrial plant.

It is possible to deliver complete installations with the help of engineering contractors, the so called "turn-key" solution, for areas which intensively use vibratory equipment.

Automated weighing installations, thermal processing of bulk materials, surface finishing, materials size classification and others are part of the overall solutions possible to contract with Mavi.

We could mention the installation of various batching systems in great foundries, glass and steel plants, fertizer classifying systems with conveyors and screeners, cooling system for monosodium glutamate, flour, carbon powder and many others.

Dosing, feeding and conveying systems for the pharmaceutical and food industry are part of the spectrum possible, rubber pellets coolers and conveyors, mixing plants for rubber components, etc., also.

With Mavi´s coordination or subcontracted help the automation and modernizing of existing outdated plants is possible, replacing old machinery and revamping the control systems to modern computerized units.

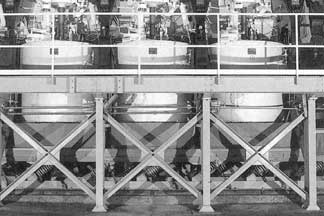

In this page we present a Mavi solution for a big company producing automotive tires, regarding the processing, conveying, cooling, distribution, mixing and blending of different rubber pellets and some special equipment for the sugar industry.

REVITRAN conveyors and coolers start the process by waterquenching hot rubber pellets, later drying the product in a set of VIPROC air coolers. Later on they are elevated and distributed by vibratory MAVICOL elevators.

The process finishes when different rubber pellets are stocked in specific deposits by means of a special rotating vibratory feeder and, when needed, extracted from the deposits by a special blending vibratory conveyor VICAL type.

A MAVI solution including the project, the manufacturing of the equipment and the start-up supervision.

MAVI may help find a solution for your specific needs.