Screening and scalping

Screening and cleaning bulk materials is an old art. The very proof of it is the "Urupema" a fine meshed hand screener for the classifying of fine cassava meal, invented by Amazon indians. Al over the planet screening devices are in use.

One does not have to use such simple utensil to perfom complex industrial tasks. MAVI vibratory screeners are among those which might help and are modern alternatives for the fast accomplishment of many different separating processes.

For the screening of up to 100 m³/h or the fine classification of granules greater than 0,0075 mm please ask Mavi for a suggestion.

Rotopen

From small to medium capacities, wet or dry screening, the Rotopen universal round screener is always an option. Over 3.000 machines are running successfully in Latin America.

Velopen e Vibrapen

From medium to big capacities we suggest our Vibrapen or Velopen rectangular screening machines. VELOPEN screeners (multistage, up to 5 decks) or VIBRAPEN, one deck only, with sizes up to 2.000 x 7.000 mm, open or closed executions are possible. In stainless steel or carbon steel.

Vibramesh

A new product among the screening machines. Only the screen deck itself is activated to very high frequency vibrations, allowing the fine screening of powders down to 0,1 mm screen mesh opening. The patented system is driven by VIMOT vibrators from Mavi. The fertilizer and the ceramics industry are great users of VIBRAMESH fine screeners.

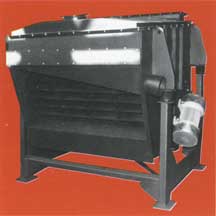

Turbopen

Turbopen rotary and simutaneously vibratory screeners are indicated for the continuous separation of fines or simply the scalping of powders before packing processes. Widely used for soy and milk powder scalping.

Separapen

These screeners are a combination of an air separation system and vibratory screener for fines which are easely blown out of the bulk material stream, like, for example the removal of shell rests from cocoa powder. Widely used in the foundry industry to clean recycled sand.