Choice

The choice of a DOSATOR® equipment is proposed from the desired capacity (required hourly flow rate), from the transport element (trough or tube) and from other accessories that can be chosen (funnel, pedestal etc).

An approximate arrangement based on the flow rate can be obtained from the capacity table (see Technical Data).

The choice of conveying element depends on the required protection or distribution. These can be gutters or pipes (gutters with or without lids, made of steel or acrylic). For totally sealed conveying, tubes are recommended, and for dosing in thin layers, troughs. Both options can be executed in ASTM A-36 steel or in AISI 304 and its alloy variants. Rubber inlet and outlet connections can also be supplied.

The drive base also offers two protection options. (Open base, protection IP-32, and closed base IP-44; see fig. 4)

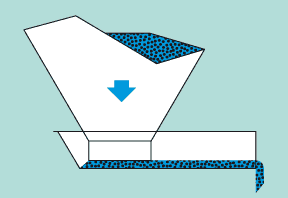

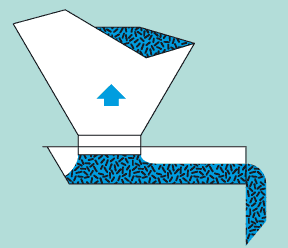

To maintain a constant flow, a funnel (volume 30L), fixed or vibratory, is added. The hoppers are adjustable, in order to control the layer thickness of the transportable material (fig. 5 and 6).

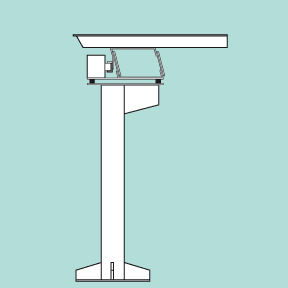

An adjustable pedestal is also optional. Its height can be regulated between 750 and 1500mm (fig.7).

Below is the coding of choice, which encompasses all options. It allows easy distinction of the equipment in queries and, if possible, should always be mentioned. (Hover the cursor over the codes below to see their descriptions).

Dosator 75 x CA - F / F / V / P