Choice

To properly choose a bin activator, it is first necessary to classify the material to be unloaded.

There are 4 defined classes.

- a. The materials of this class are granular and have free flow. Sometimes, due to changes in temperature or humidity, bridges are formed. Examples would be: food salt, sugar, plastic or polymer granules, etc. The angle of repose is approximately 30°.

- b. Material is pulvicultural, particle size between 0.045 and 0.1mm. Angle of repose approx. 45°. (Flour, starch etc.)

- c. Pulvurent material, particle size less than 0.045 mm with strong adhesion properties. (Titanium dioxide and pigments in general as well as cement, talc, icing sugar etc.)

- d. Fibrous or flocculent material, with low bulk density and grain size between 3 and 25mm. (Coarse sawdust or wood shavings, asbestos fiber, etc.)

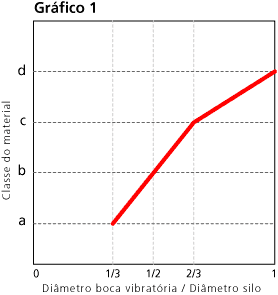

Secondly, it is necessary to determine the diameter of the vibratory mouth in relation to the diameter of the silo. The chart in fig. 11 relates the material classes to the vibratory mouth diameters. For example, a class b material corresponds to a vibratory mouth diameter equal to 1/2 the silo diameter.

Thirdly there is the need to determine the bin activator for a specified flow rate.

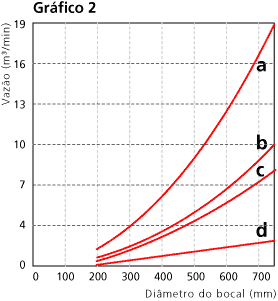

Fig. 12 relates the flow rates to the nozzle diameters as a function of the material classes. For example, for a material class b and a required flow rate of 7 m³/min, a nozzle diameter of 600 mm is required.

These selection guidelines are only general, not definitive, and therefore often subject to change, as in certain cases the materials do not fit perfectly into the aforementioned class division. They should be used only for approximate positioning of the required equipment. Further clarification can be obtained from the manufacturer.

Regarding the choice between VICONE S® and VICONE D®, the following should be remembered:

Normally the VICONE D® type fits for class d materials, this however is not definitive, as in some cases the VICONE S® type is also possible. (see applications) For this it is necessary, in some cases, a deeper analysis of the material by the manufacturer and possibly a small test to observe the flow properties through the bin activators.