How to choose Vimot vibrators

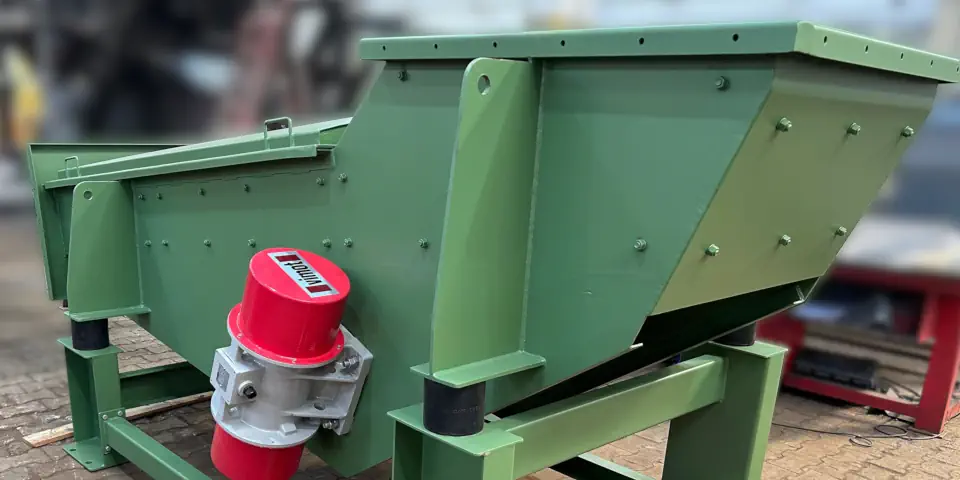

Transport and feeding

To use vibration motors in conveyor systems like chutes (up to 10 meters long) or feeders (up to 1,500 m³/h), the selection procedure is similar.

However, it must be considered that the ratio between the acceleration of the equipment and the acceleration of gravity should be in the order of 1.5 to 3.5. For light materials (fibrous, light powders, granules with apparent density lower than 1.0 t/m³) between 1.5 and 2.0 and the others above.

For materials that must be transported with maximum silence and protection, a ratio of 1.0 is recommended. (Castings, large parts in general, wood, forgings, etc.)

The other procedures for determining the type of vibrator are the same as those indicated for vibrating screens.

For vibrating transport, knowing the section through which the volume of material will pass, the flow rate can be determined by a very simple relationship, indicating the transport speed as a function of the vibratory amplitude.

For light equipment (up to 200 kg) we recommend 4 mm of amplitude and 1750 rpm. With the vibration motors fixed at 30 degrees, we will have a transport speed of 12-15 cm/s.

For medium equipment (200 up to 3,000 kg) the amplitude should be 6-8 mm, producing a conveying speed of 15-20 cm/s. A vibratory frequency of 1,150 rpm is recommended.

In heavy equipment (above 3,000 kg), we suggest amplitudes between 8-12 mm with resulting speeds also of 15-20 cm/s. Frequency of 875 rpm suitable.