A multitude of applications

Compacting

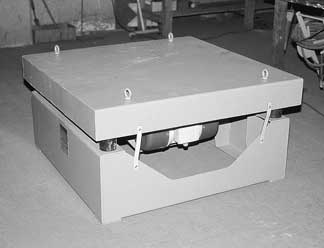

Vimot® Motovibrators, mounted on vibrating tables, can completely compact packages and their contents, reducing the space between particles, expelling air. In this accommodation the transported volumes, with the same weight, become smaller.

Another application for compaction would be the better accommodation of foundry sand in molds, when vibrated on high or very high frequency tables.

In some cases, such as the lost mold process (instead of another counter-mold or core, a Styrofoam molded part is used), vibration is even required to perfectly fill all the gaps around the mold.

Some companies have used the Vimot® vibrators for soil compaction, mounted on skid plates or small sleds. Soil compaction (or concrete smoothing) with vibratory motors brings excellent results for durability and appearance.

Pre-compaction of sand in fuses, so that this does not occur during transport, is also a task easily performed by vibration tables equipped with Vimot® vibration motors.

We cannot forget the very common use of vibrating and deaerating molds for concrete. The higher the vibratory frequency and impact, the better the mold surface appearance and internal strength.