Applications

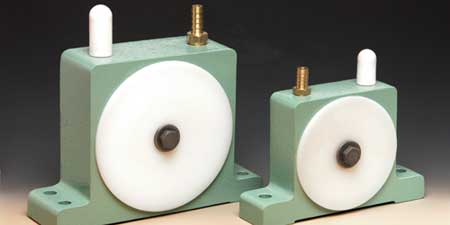

When it is necessary to apply very high-frequency vibrations in silos, ducts and warehouses, in order to obtain good aid to the flow of bulk materials, and also to need equipment with very small dimensions, one can opt for LuftMax Turbo® pneumatic vibrators.

They are simple to operate, require minimal maintenance and, thanks to the new concept used by Mavi Vibratory Machinery for their construction, are extra long-lasting.

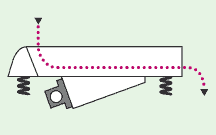

Below are some examples of their applications and working positions, in order to obtain their best use. They work in high temperature environments, (up to 100°C) if necessary.

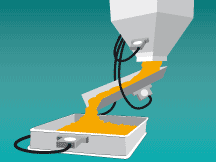

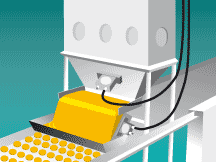

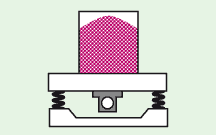

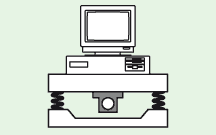

LuftMax Turbo® Vibrators can also be used to drive small conveyors or feeders, or even vibrating screens for classifying materials or filtering liquids.

The low amplitude developed reduces possible fatigue stresses on materials in silos and pipelines. The high frequency of LuftMax Turbo® vibrators (up to 33,000 rpm) creates powerful accelerations, which can help convey a wide range of bulk materials.

They are very economical in air consumption and start their vibratory work already at pressures of 1 bar (15 psi).