Some considerations about choosing

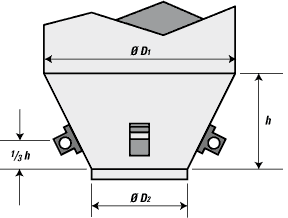

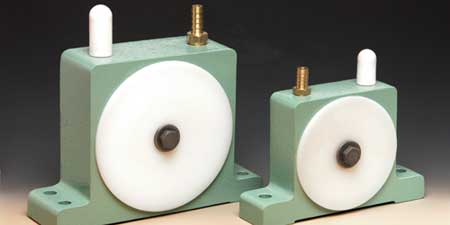

For vibrating silos, tanks and pipelines, we can start from the basic consideration of using turbine vibrators for their excellent starting characteristics at relatively low pressures. In the case of silos, the choice is determined by the volume of the conical part of the silo, remembering to always set the LuftMax Turbo® vibrators at 1/3 of the height of the cone, starting from the smallest diameter (see illustration beside).

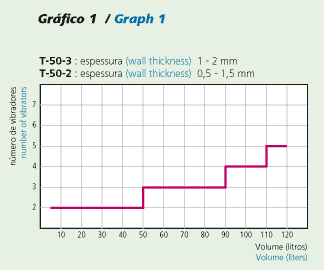

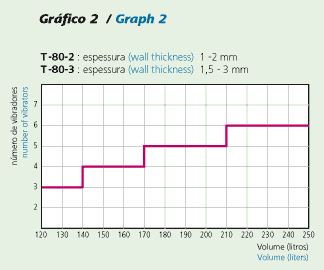

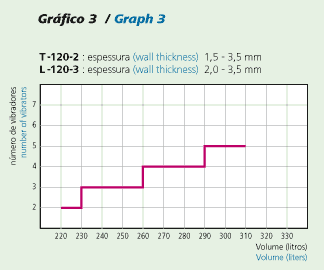

For applications in silos, bins and ducts requiring more intense vibration, the vibrator options with lower frequencies are recommended (models T-50-3, T-80-3 and T-120-3).

The graphs on the right allow an approximate choice of the type of vibrator recommended.

The basic quantity of LuftMax Turbo® vibrators is determined by the discharge cone volume of the silos and bins, as well as the plate thickness.

The cone volume is calculated (for round sections, the most common) with the following formula:

V = 270.h.(D1²+D1D2+D2²)

(V in liters and h, D1 and D2 in meters)

With the values obtained for V = volume in liters and the help of the graphs beside, the size and quantity of LuftMax Turbo® vibrators is determined.

For moist or sticky materials, multiply the quantities by 1.5, rounding the value obtained to the next higher integer.