Execution

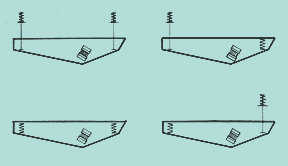

VICAL-T conveyor chutes have several types of executions designed for different applications. Their attachment can be chosen depending on the installations in which the troughs are to operate. They can be suspended or supported or a combination of both. The diagram on the right shows the different possible options for fastening the trunking.

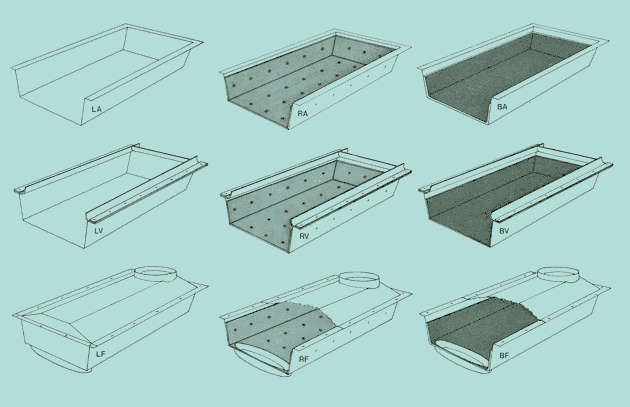

The other diagram below shows us 9 possible combinations of inner linings or seals. The internal liners depend on the type of material to be conveyed. Sticky, abrasive materials require rubber liners in the chute (types BA, BV, BF); highly abrasive materials lining with wear plates, replaceable after wear (types, RA, RV, RF). Materials that do not exhibit the above characteristics can be conveyed in so-called light-duty chutes (types LA, LV, LF).

To eliminate the propagation of dust during transport, you can opt for seals with rubber flaps attached to the top of the chute flaps, closing the space between any discharge mouths or tank outlets and the chutes (types LV, RV, BV). Another solution can be the totally closed type (types LF, RF, BF).