Planning

The planning for the incorporation of vibratory equipment in industrial installations must be done taking into consideration the multiple possibilities that this equipment has. Many times they allow the efficient replacement of conventional equipment (such as conveyor belts, for example), which must be verified mainly in the subsequent maintenance that is minimal.

However, it is up to the planner to choose the appropriate conveyor chute, based on the information contained here, in order to facilitate his work.

In the following we will show several examples of VICAL-T vibratory channel designs which will give the planner an overview of the possibilities. Naturally other designs and combinations are possible, which in some cases may require further consultation with the manufacturer.

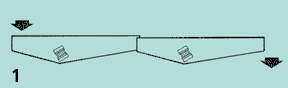

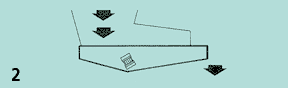

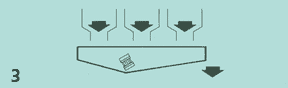

Grouping for greater distances is done with several chutes arranged in series (fig. 1). The troughs can receive feed at one point (silo mouth or bin) as shown in fig. 2 or at several points (fig. 3).

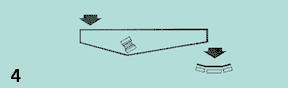

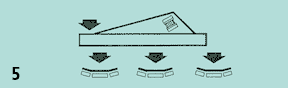

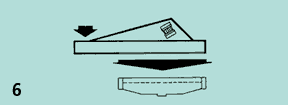

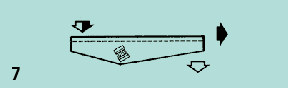

The same happens in relation to the discharge, which can be single point as we can see in fig. 4 or multi-point. In fig. 5 we show the unloading for three belts. Sometimes it is necessary to make a uniform distribution of the material to be conveyed in the discharge, this can be the case in feeding vibrating screens, processing cylinders (as in grinding for example). This can be the case when feeding vibrating screens, processing cylinders (as in milling, for example). In this case, the so-called \"chute slot\"" is used. For this, see Fig. 6. The vibrating trough can also be equipped with a through bottom to allow for the screening of products during transport. See fig.7.

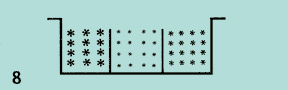

To transport already separated products in a single chute we can subdivide it into several lanes as shown in fig.8.

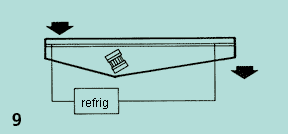

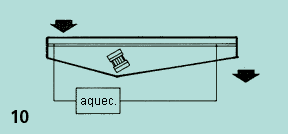

Often in industry it is necessary to thermally process materials during transportation. In vibratory troughs this is done by means of a double bottom through which a cooling or heating fluid can run in order to remove or add heat to the conveyed product. Other processes such as drying, moistening, etc. can also be carried out during vibratory conveying, by means of special devices such as fans, sprinklers, etc.

"