Electrical controls

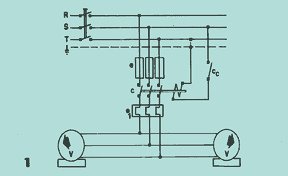

Beside are the connection diagrams for the VICAL-T conveyor trunking. The circuit in 1 shows the usual connection with the following details:

Protection device that encompasses the fuses e and the adjustable thermal relay e1. Interlocked is the switch c operated by the control circuit Cc for automatic or manual commands. It is important to note the direction of rotation of the vibrators V (one opposite the other) because without this precaution the conveyor chute will not operate properly.

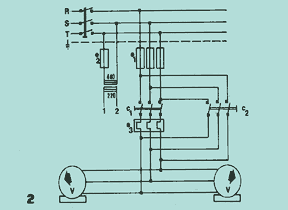

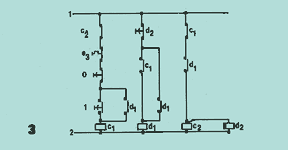

Diagram 2 shows the circuit for counter-current braking. In general, vibrating machines have large beats when turned off because the V vibrators pass through critical speeds when slowing down. To eliminate these vibrations, the free rotation time of the vibrators is reduced by counter-current braking. Control circuit 3, guided by the timing relay d2 injects counter current through switch c2 for a period of 2 seconds.

The counter-current is produced by allowing switch c2 to reverse the supply phases (RST). This type of circuit is very useful for vibrating machines that do not work continuously but only for a few moments, in rapid sequence.