Execution

ELMAVI feed chutes have several types of executions, designed for different applications.

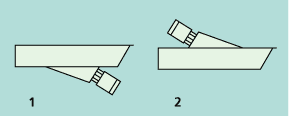

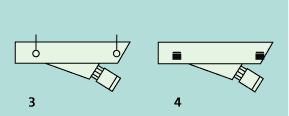

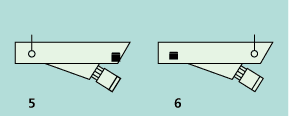

Its fixation can be multiplied according to the type of silo mouth, tank or similar. The diagram above shows the different possible options for fastening the chute. The black blocks symbolize supported fixings, and the dashes suspended fixings.

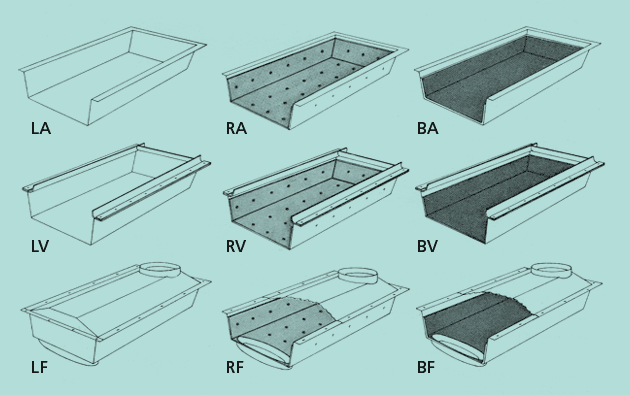

The other diagram shows us nine possible combinations of inner linings or seals. The inner liners depend on the type of material to be conveyed. Sticky, abrasive materials require high molecular weight rubber or polythiophene liners in the chute (types BA, BV, BF); highly abrasive materials require wear plate liners, replaceable after wear (types RA, RV, RF). Materials that do not exhibit the above characteristics can be conveyed in so-called light-weight chutes (types LA, LV, LF).

To eliminate the propagation of dust when extracting materials from silos or bins, the chute with seal (types LV, RV, BV) is recommended. Rubber sheets attached to the top of the chute flaps seal the gap between the discharge mouth and the chute. A fully closed model is also available (types LF, RF, BF).