Applications

To facilitate the stocking or storage of bulk products, there has been a trend lately to build larger silos, up to 10 m in diameter.

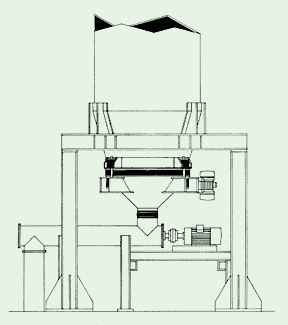

Vibrating inlets with diameters up to 3,400 mm are therefore viable for the extraction of materials from almost any size of silo.

This extraction can take place directly for the loading of means of transport (trucks, wagons, etc.) or for the feeding of subsequent equipment in a production line (screws, vibrating conveyors or tubes, screeners, scales, etc.).

In some cases dosage is required from the bin activator. For this purpose, interleaved vibration is applied, as follows:

By the timing of the operation, the momentary occurrence of vibration causes tensile stresses in the material. Since bulk materials have little tensile strength, the bridges or chimneys will be destroyed.

In the intervals of vibration, the material will again form bridges after a certain period of time, and the flow will be contained. As soon as this occurs, the vibration mouth is activated again, and the bridges are broken.

This is done for 2 to 5 seconds.

Adjusting the stop period of the vibrating mouth, one can then dose the product to be discharged. There are no exact rules to indicate the best type of vibrating discharge mouth. However, there are a number of recent VICONE S® type applications that allow extrapolation to a good range of materials. For example:

All types of coal can be handled by the discharge vibratory mouths. Coal with a particle size of 0.3 mm and 15 to 20% moisture content is one example that is perfectly manageable.

Wood sawdust has always been considered very difficult to stock and extract from silos, but has not presented problems with VICONE® bin activator.

In the extraction of chips of polyethylene film, polypropylene, polystyrene and similar substances, the VICONE S® type was also found to work well.

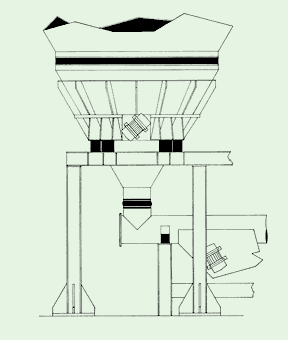

The apparent density of these materials is between 0.01 and 0.15 t/m and, with small granulometry, does not present problems. For chips larger than 10 mm, however, the VICONE D® type must be used.

VICONE D® has been successfully used to handle a wide variety of materials.

Among these are the lightest type, carbon black, with a density of approximately 0.034 t/m³, and the heaviest, magnetite, with 2.5 t/m³.

The settling factor is an important consideration to be taken into account when applying vibrating discharge nozzles.

Wheat flour, for example, will settle so much after 12 hours of storage that it will hardly drain. For products, then, that have a high settling factor, the VICONE D® type bin activator is proposed, as its vertical vibrations desagregate the settling.

We also remember that the equipment's internal abrasion is minimal. There are vibratory mouths in operation for more than 5 years without major internal wear.