Types of sealing and finishing

Flexible connections for sealing (between discharge vibratory mouth and silo, and between discharge and subsequent equipment), are normally made with natural rubber of thickness equal to 5 mm. Connections can be made with thicker rubber as well as other materials such as neoprene, hypalon, white neoprene, etc.

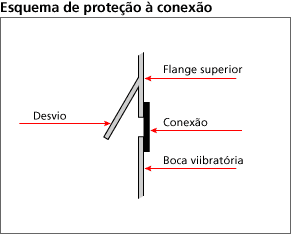

The diagram on the right indicates the type of protection made to the rubber connection, through a deviation made in the upper connection flange. This protection prevents abrasion of the connection as well as temperature rise in the case of hot materials.

Otherwise, it prevents material pressure on the connection, which could interfere with the operation of the VICONE® bin activator.

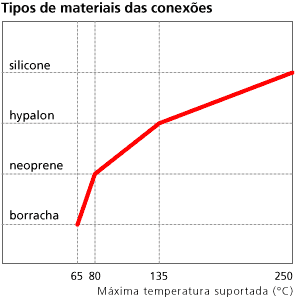

The limitations of the type of material of the connections are highlighted in the graph beside, in comparison with the maximum tolerable temperatures.

The constructions can be made of different materials, preferably steel or stainless steel (widely used in the food industry).

The internal finish depends on the type of material to be discharged and can be made of rubber, Teflon and other materials.

This mainly depends on the user's specifications.