Operation

The Rotopen vibrating screen is basically a system that vibrates around its center of mass, the vibration being provided by an electromechanical Vimot vibrator, to whose shaft ends two eccentric masses are attached.

The vibrator having been fixed vertically, its upper and lower eccentric masses produce three different types of vibration. The upper mass, when rotating, provides vibrations that dispose the material to be screened, horizontally on the screens. The rotation of the lower mass produces tangential and vertical vibrations which activate the material to micro-jump over the screen plane, thus forcing it through the meshes.

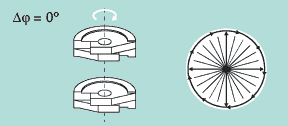

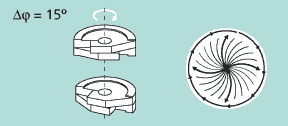

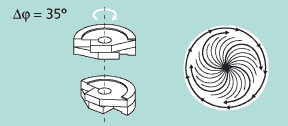

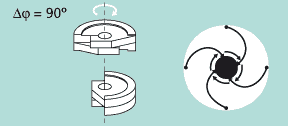

Depending on the type of material to be screened, a variation in the distribution of the material on the screens is necessary. This is achieved by positioning the upper and lower eccentric masses at different angles.

It should be noted that the lower mass leads the upper mass when they are rotating. Therefore, when positioning the masses, you must make sure that the lower mass is, under a certain angle, ahead of the upper mass, always in the direction of rotation.

See the diagram beside for different distributions of the material to be sieved, on the screen, as a function of the gap Dj between the upper and lower eccentric masses.