Operation

All the different types of VELOPEN vibrating screens are driven by a set of self-synchronizing VIMOT vibrators, which rotate inversely to each other. In this way, linear vibrations are produced, which, directed at an angle of 40 to 60 degrees against the screens, drive the material over the screens towards the discharge mouths at a speed of a few centimeters per second, and force the material to pass through the meshes.

There is therefore no need to tilt the sieve for the material to be conveyed. This can be done in specific cases to increase the conveying speed. In case it is necessary to overcome a certain height for unloading, the screen can be elevated by 10º, and then an inclined conveying will occur.

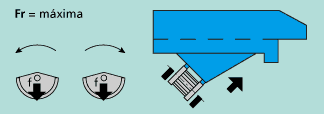

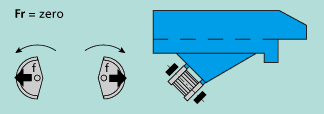

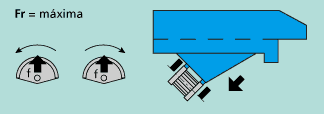

The adjacent diagram explains the operation of the sieves in simple strokes, showing how the resulting vibrating force Fr, resulting from the rotation of the inertial masses attached to the shaft ends of the VIMOT vibrators, is produced.

The arrows on the sieves pictured indicate the direction and direction of operation, according to the reaction of the resultant force.

Clogging of the screens is unlikely to occur because the vibrating force accelerates the particles at approximately 40m/s², which should certainly displace the vast majority of the particles on the screen.