Operation

The basic design of the MAVITRON is quite simple. The vibrating action is transmitted to the processor channel by means of a vertical vibrator, mounted directly in the center of the processor tube.

The eccentric weights placed on the upper and lower ends of the shaft allow, with their various adjustments, the control of movement and speed of parts being processed.

The vibratory action on the work load composed of abrasive bodies, chemical additives, and parts, is responsible for the degree of finish required.

The processor channel can work with up to 85% of its volume occupied. The vibrating action forces the load to describe a helical movement around the central tube, giving all parts a uniform and simultaneous finish.

The MAVITRON can be operated as a continuously operating automatic or batch finishing machine, also with automatic operation.

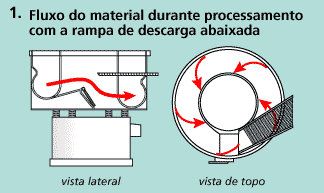

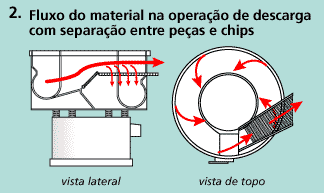

In the batch work, the operator selects the time required for the work cycle in the timer (optional) installed on the machine panel. When the programmed time is reached, the unloading ramp is activated by a pneumatic piston (optional), unloading the parts.

In continuous operation, the ramp remains in the unloading position. The parts are continuously fed into the processor channel and after one orbit are unloaded by the discharge ramp.

In the discharge channel there is a screen or perforated plate that promotes the separation between the abrasive bodies, which return to the operation and the parts, already finished, are discharged.

To remove the abrasive bodies and clean the machine completely, simply place a flat plate on the screen in the discharge nozzle.

The addition of liquid compounds during the process helps to keep the abrasive bodies clean, improving their ability to operate and eliminating impurities from sticking to the processing channel.

There are two compound addition systems available:

Continuous System

A metering pump regulates the compost+water mixture that is continuously sprayed into the processing channel through the spray nozzles. Dirt and fines are discharged into a tank, and used compost can be discharged directly into the drain (provided it is biodegradable).

Recirculating system

It is used when product discharge generates pollution or where the cost of water is high. This system makes the compost+water mixture recirculate between the tank and the processor channel. Periodically the mixture must be drained and replaced.