Introduction

VELOCAN vibrating conveyor tubes driven by electromechanical VIMOT vibrators are mainly used for conveying or metering bulk materials, overcoming distances of up to 7 m or more when combined in groups, forming conveying lines. They can operate on a constant, temporary, or intermittent basis according to needs, conveying especially those materials with a high concentration of fine or powdery particles.

It is usually desired to eliminate the propagation of these particles, so a closed and sealed construction of the pipe is recommended.

The VELOCAN tubes are subjected to linear vibrations under a certain angle of inclination caused by the VIMOT vibrators, activating the product in the tube to be transported by means of micro jumps. These jumps produce a smooth movement, without excessive abrasion.

The oscillation of the tube (double amplitude) is in the order of 4 to 10mm and the conveying velocity varies between 25 and 30cm/s. The conveying speed can be regulated by convenient positioning of the inertial masses of the vibrators (see Vimot).

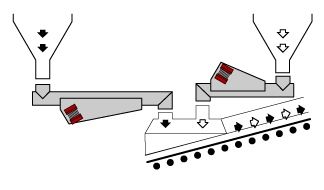

Below is an example of the application of vibrating tubes for feeding a conveyor belt.