How to choose Vimot vibrators

Screening

In this case the material particles on the screen should be vibrated with a good frequency, oscillation equal to or greater than the screen opening, and a ratio between the vibration acceleration and the acceleration of gravity between 3.5 and 6.5. This means that the acceleration of the vibrating equipment or sieve should be 3.5 to 6.5 times the acceleration of gravity (approx. 981 cm/s²).

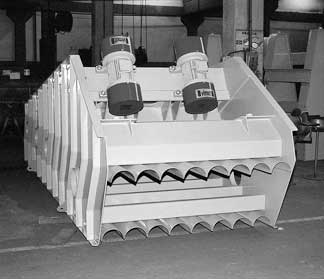

If the screen is horizontal, two Vimot® motovibrators are used, one rotating in the opposite direction to the other, in order to eliminate unnecessary horizontal vibrations.

If it is inclined (about 30 degrees) only one vibration motor is enough, because the transport component is given by the inclination. Check the illustrations on this page about it.

The acceleration of the equipment is given by the following formula:

0,0039 x A x N x N

where A is the vibration amplitude in cm (usually between 0.4 and 0.8 cm) and N is the rotation in rpm (between 875 and 1,750 rpm) of the equipment.

If we divide the result of this formula by 981 (value of the acceleration of gravity) we will obtain the factor that indicates how many times the equipment is accelerated in relation to gravity. If it is between 3.5 and 6.5 it will be suitable for sieving. The higher the factor the better for fine materials and tighter screens.

For example: material to be sieved on a 5 mm screen in a horizontal sieve.

A frequency of 1,150 rpm is usually used to drive medium sieves, 1,750 vpm for light sieves, and 875 rpm for heavy sieves.

The acceleration for a medium sieve should be:

0.0039 x 0.5 x 1,150 x 1,150 = 2,579 cm/s²

Where 0,5 is the amplitude in cm (equal to the screen opening) and 1150 is the rotation or vibratory frequency in rpm.

Dividing this obtained acceleration by the acceleration of gravity (981 cm/s²) we have:

2.579 / 981 = 2,63

which is insufficient for sieving, so we must change the amplitude to a higher value or the frequency. For example, if we use the amplitude of 0.7 cm we change the formula to :

0,0039 x 0,7 x 1.150 x 1.150 = 3.610 cm/s

With this the result is

3.610 / 981 = 3,68

approximately, therefore sufficient for sieving.

To choose the appropriate vibration motors, we already have the frequency (1,150 rpm) set.

To determine the final model we just need to know what torque is needed to make the weight of the sieve vibrate with 0.7 cm amplitude.

It is simple:

T = P x A

where T is the torque in kg x cm

P is the total weight of the equipment in kg

A is the vibration amplitude in cm

Let's say that your equipment weighs something around 350 kg and the vibration amplitude is 0.7 cm, so we will have a torque of:

350 x 0.7 = 245 (kg x cm)

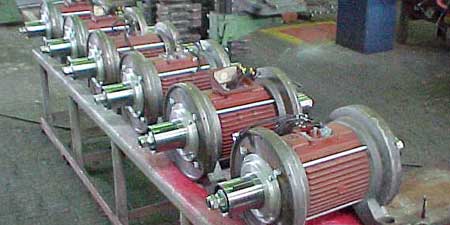

Then just choose two vibration motors of 1,150 vpm whose individual torques added together equal 245 (kg x cm) or more.

"